Adiabatic Solutions

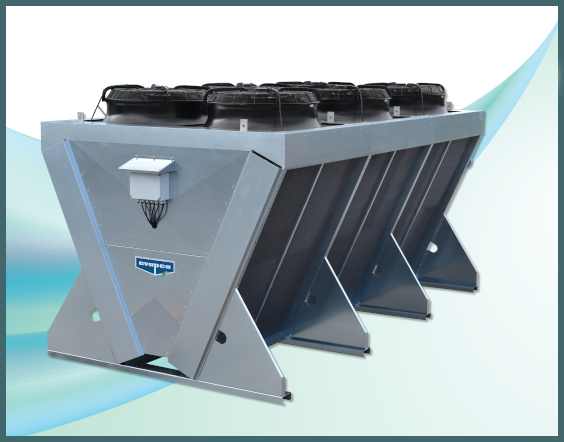

Adiabatic solutions

EVAPCO Europe's units with adiabatic pads or spray, are designed to permit the most flexible, economical and hygienically safe cooling system available today.

The product allows cost-effective dry cooling during applicable temperatures combined with economical pre-cooling of the entering air to achieve operating temperatures like evaporative equipment.

The control sequence is designed to enable the unit to adjust accordingly to achieve the lowest energy and water consumption as ambient conditions change.

The Adiabatic pad or spray solutions can be added to single and double coil arrangements with various combinations to meet your needs. The system can be fully integrated with modern modbus control systems or manual controls to fit the customer’s needs.

Features and benefits:

- Reduces water consumption, and therefore ongoing cooling equipment costs.

- Minimizes and eliminates problems with scaling, corrosion and bacteria.

- Reduces maintenance, which are traditionally associated with fully evaporative systems.

- No need for pump or basin to store water (also reduces maintenance)

- Adiabatic pads filter and limit the unit's exposure of dirt and debris to the heat transfer surface.

- Option for fan- and motor selection that does not require routine maintenance.

Adiabatic Pre-cooling system

- Wetted pads can be utilized for pre-cooling entering air, resulting in greater energy savings,

and increased capacity, with minimal water use - Great for high ambient dry bulb climates or high temperature applications

- Once-through design

- No water treatment required

- No cold water basin or pump

- No drift

Adiabatic Spray assist system

- Ideal for high ambient dry bulb climates or high-temperature applications

- Tangential flow nozzles

- Once-through design

- No cold water basin or pump – eliminates winter operation concerns associated with evaporative equipment

Adiabatic principle of operation

Basic operation, on a fully controlled unit, energizes the electromechanical valve system as the final step in the control sequence to reach the leaving water or refrigerant set point. Once all motors have reached full speed and the set point is not met with air only, the electromechanical valves energize and the water comes on. The dead band range prevents the valve body from oscillating on and off and allows the system to run to minimize thermal shocking. Using step control, the electromechanical valve system will energize after the last motor is energized and the set point triggers the valve to open.

Adiabatic coolers uses 70% less water than standard evaporative cooling devices.

Products

Downloads